Heat Treating Music Wire

This is not a heat treatment. Wire springs are placed in an oven or furnace for a certain time and temperature to relieve stress as well as to temper the spring wire to give the spring.

Promag Ber 21a Bobcat 22lr 7rd Blue Liberty Sport Pawn

That is to soften it form or bend to desired shape and then re-heat treat the part back to the spring condition.

. In addition Material Specifications TemperatureC F Time. Spring wire that gets coiled has to have the bending stress relieved. 1 888 322-9974 Music Wire - ASTM A 228 - Spring Wire Properties Spring Materials High Carbon High-carbon spring steels are the most commonly used of all springs materials.

This treatment increases both the elastic. Stress relieving is the most common heat treating operation. Also known as music wire.

Music wire doesnt need any heat treatment the wire is already in the spring temper condition. Wire Straightening and Cutting Centerless Grinding Double End Chamfering Wire Stock Parts Tooling Wire Machinery Sales 247 Technical. If the wire is already coated.

Spring Wire Heat Treatment. Definition of Heat Treating Springs. This wire is coated with.

It is a stress relief. - the wheels collars pants etc. Preheat your kitchen oven.

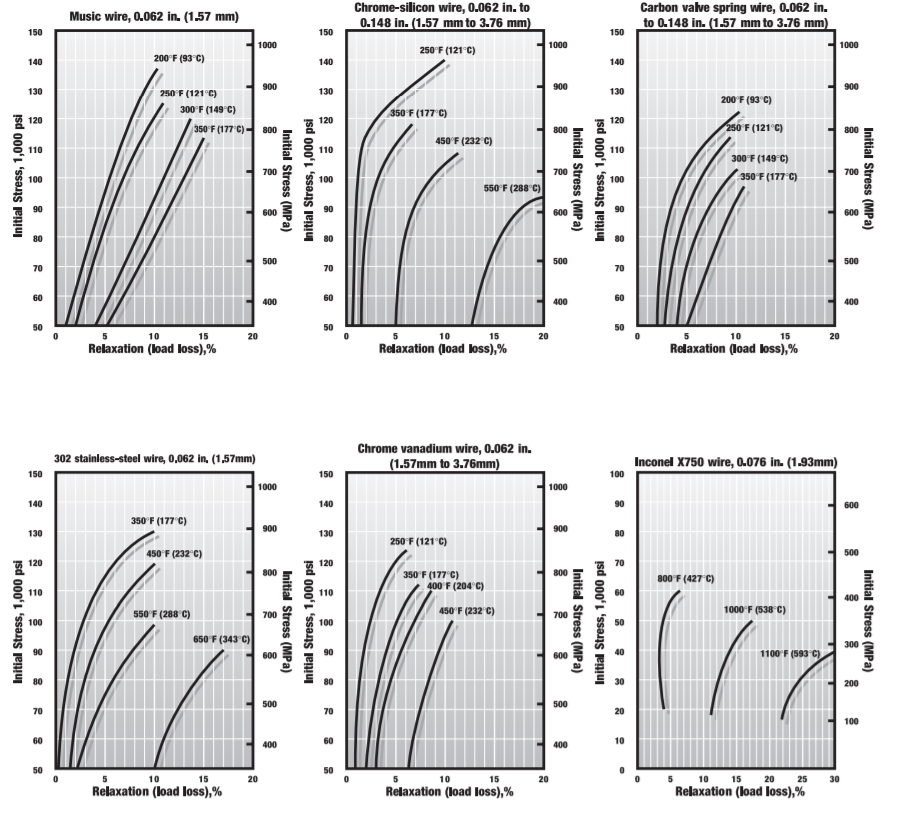

Music wire high carbon steel is heat treated after being drawn and before being wound into a spring. The residual stress is a function of distance from the surface for CrV and CrSi wire after stress relieving Fig. F irst the w ire should be annealed at the location to be bent.

A possible solution is to remove the gear from the airframe and remove all the hardware from the gear wire ie. T o anneal heat. Low-temperature heat treatment 260 to 290C of music wire after coiling relieves stresses within the wire due to cold work performed in coiling.

Following winding theres a mild re-treatment to remove stresses in the. Heat Treating Music Wire - by Roy Vaillancourt. Heat Treating Music Wire by Roy Vaillancourt An Article published in the December 2012 Issue of the Sam 26 Coastal Flyers Newsletter Bob Angel Editor To form wire easily first anneal it.

Lubricated 1080 Spring Steel Wire. ERA WIRE is your One-Stop-Shop for. Heat Treating Music Wire by Roy Vaillancourt An Article published in the December 2012 Issue of the Sam 26 Coastal Flyers Newsletter Bob Angel Editor To form wire easily first anneal it.

The music wire used by modelers to make landing gear and cabin struts is medium carbon steel heat-treated to spring.

Promag Bersa Series 95 Thunder 380 Magazine 380 Acp 10 Round Blue Easy Loading Rugged High Carbon He Bra04 1037543

Performance In Wire Voestalpine Wire Technology

Beginner S Guide On How To Anneal Steel Make It From Metal

Steel Wire Heat Treatment Line

China Customized Music Wire Compression Spring Factory Music Wire Compression Spring Free Sample Zihuoli

Guide To Spring Materials Wb Jones

How To Make Springs 9 Steps With Pictures Instructables

Suspension Spring Manufacturers China Customized Products Gold Star Spring

Astm A228 Music Wire Nqa Iso Certificated Factory

General Wire Metal Hair Snake In The Hand Augers Department At Lowes Com

Mec Gar Para Ordnance P18 38 Super 17 Rd Magazine Nickel Mgw

Induction Heating Applications For Wires Strands Ropes Strips And Profiles Applications Ate

100pcs Set P75 E2 Spring Test Probe Pogo Pin 1 3mm Conical Head 1 0mm Thimble For Power Tool Amazon Com

Common Spring Materials

Mec Gar Ruger Mkiii Iv 22lr 10 Round Magazine

Astm A228 Music Wire Nqa Iso Certificated Factory

Music Wire Tools Supplies